How to effectively prevent the table saw from rebounding, safety production should run through all the time!

Safety should be the priority in everything, especially in production. Only by ensuring basic safety can we talk about other goals and pursuits.

Because furniture production involves operations such as sawing, cutting, and drilling. It also faces energy sources such as heat, electricity, and gas. As small as saw blade injury, as large as explosion and fire casualties, safety accidents in the furniture industry are not uncommon in recent years. Therefore, the awareness and methods of safe production should run through.

Today we take the sawing equipment - table saw as an example, talk about how to effectively avoid safety accidents, and call on colleagues in the industry to pay more attention to product safety issues.

A table saw is the first significant piece of equipment most woodworkers buy. This versatile tool can cut wood in any direction (straight, cross, or beveled).

When the table saw is processing objects, there is a safety hazard called "rebounds." When a part of the workpiece is sandwiched between the saw blade and the lean or other fixed objects, it will bounce back, bounce off the table, and fly to the operator, causing injury.

In general, rebounds create two dangers:

First, the bouncing board directly hits the operator;

Second, if the operator is holding the board through the saw blade, the hand will be dragged toward the saw blade before he can even react.

What measures can we take to avoid the rebound situation as much as possible?

1. Make sure the saw blade is parallel to the vertical backing, and adjust it in time if it is not paralleling.

2. When cutting longitudinally, do not apply push force to the part of the workpiece where the uncontrolled residual material is cutting.

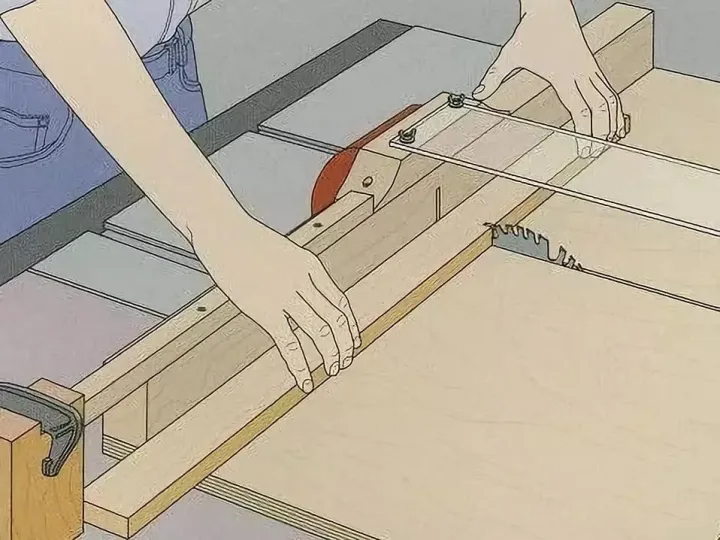

Use a push tool when you are close to the blade. It is a must to use special fixtures for very small workpieces.

3.

Make sure the guard, riving knife ,and anti-kickback teeth are in place and working properly.

Keep the anti-kickback teeth sharp, the splitting knife should be in line with the saw blade, and the anti-kickback teeth play a role in preventing kickback when a kickback occurs.

Check its working condition before sawing, and test it by pushing a piece of wood under it. The anti-kickback teeth should prevent the wood from being pulled to the front of the saw.

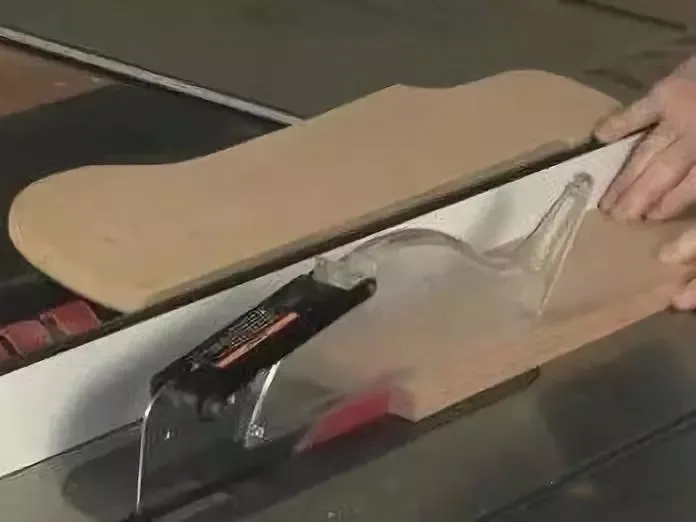

4. Composite materials need extra attention when cutting, as these materials are very hard and smooth, and anti-kickback teeth may not be able to prevent rebounds. Therefore, special care must be taken to follow proper setup and cutting procedures when cutting such materials.

5. Use guards for every operation whenever possible.

And before using the table saw, the operator must carefully read the safety operation specifications of the relevant table saw. Ensure ownself safety.

Recommend

-

-

QQ Zone

-

Sina Weibo

-

Renren.com

-

Douban